Log Buildings

About Our Log Buildings

*Construction Information PDF

We pride ourselves in creating custom buildings unique to each customer's needs. We have a general system that we begin with, but we work with every customer to ensure that specific needs are met. Our buildings are always delivered as fully built "sections", or in many cases, as a fully completed building. This allows for you to prepare the building site, while we build your custom log building in our shop. We deliver our buildings on a tilt-and-winch style trailer with rollers, and can use skid steers to move buildings into place if needed. (Note: We strive to get the building in on the trailer as far as possible, hopefully within feet of the building site. Please be sure a building of the size you are ordering can be navigated near your desired location.)

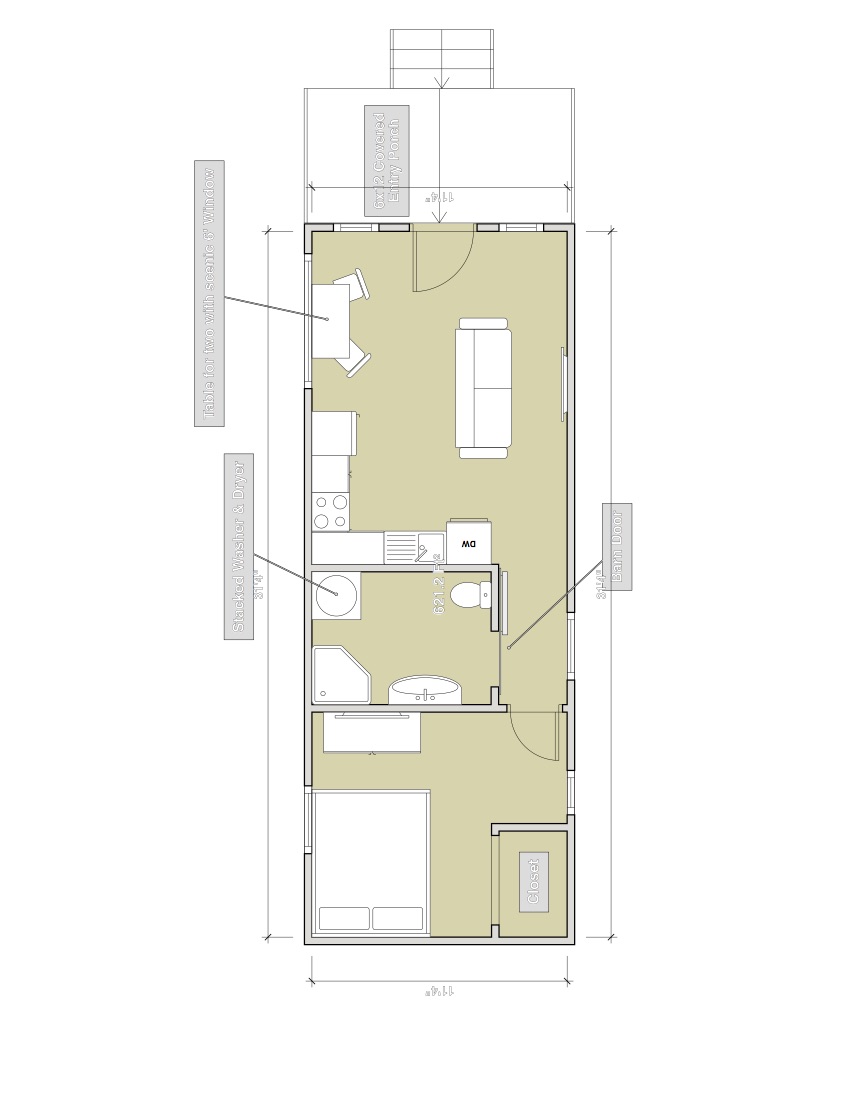

Given that our buildings are delivered to you, we keep our buildings to a limit of 12' in width and 32' in length. If you building needs are within these limitations, then your building can be delivered and set up in a matter of minutes! If you need more square footage, we can build several units or sections that will be attached upon delivery. A building order of 2 to 3 sections can still be delivered and finished in a matter of a couple days!

All of our buildings are built of quality kiln dried 4"x6" pine logs. Each row is pulled together with high-grade 8" lag screws and a construction adhesive. With this process we can nearly eliminate all log separation and re-chinking needs that are common with other log buildings! Our buildings can be broken up into rooms using the same log system, or using 2x4 studs and our tongue and groove pine siding.

Once the basic "shell" of the building has been figured, you can then begin to plan for various entrances, windows, doors, decks, cabinets, flooring, roofing, stains, etc.

Doors: You may change or add entrances and windows to your liking. Some doors may be quite simple additions, while some can be larger gabled entries with decks and added ceiling space. !

Windows of various sizes, colors, and functions can be added to customize your building. Our stock windows are Double-pane, and come in 4 sizes (2x3, 4x3, 6x3, and 4x1 Transom)

Flooring: Buildings come standard with plywood, but we can add our own pine board flooring or your choice of manufactured plank. Our floor joist system is all ground contact pressure treated lumber, and can be set directly on the ground if needed. (Although we recommend blocking, piers, concrete slabs, or crawl spaces)

Roofing: We use Wheatland Steel for our roofing. Currently there are over 20 colors to choose from!

Wood Stain and Stabilizer: You may choose different tones for the interior surface of the logs. The logs with then be coated with a clear protectant designed to be Step 2 of the log treatment process. As with other wood buildings and surfaces, your building will need some maintenance in the future. A general rule of thumb is that you will need to apply a protectant coat every 4-6 years. We recommend using a pump sprayer and following up with a brush to remove any running of the product.

Heating and Cooling: There are many options to heat and cool your building. Here are a list of options that we can supply: electric baseboard, wall mounted AC, and wood burning stoves. All other heating and cooling options will be completed by the customer after the building is delivered and set. (gas fireplace, heat pump, forced air, etc.)

Electrical: Most of our buildings are wired, and with solid log walls it makes running wire a little more more difficult. We drill holes for running wiring up walls during the building process. Wire running horizontally is trenched into the bottom row of logs and then covered with a trim board. Wiring can be run in the ceiling much like common building systems, which gives you the option of ceiling lighting and fans. As for outlets and switches, you can customize placement to fit your needs. On single building units, your fuse box will already be signed and dated to code and all you will need to do is get power ran to the box. On multi-unit builds, the customer will be responsible for finalizing hookup between each building section at the electrical panel. (Wires will already be ran up to the panel, and labeled)

Decks: We can create decks of various sizes and designs to fit your needs. We try to have deck and railings prebuilt in sections that are delivered on a separate trailer, to ensure we keep the delivery and setup process quick and mess free!

Additions: We create custom pine cabinets, Murphy Tables & Beds, as well as other various functional items for your building. We also have a direct connection to beautiful local handmade Aspen log furniture at great costs! (Dinner Tables, chairs, beds, dressers, coffee tables, nightstands, end tables, and more!)

Cabin Interior Pics

Cabin Interior Pics  Cabin Furniture

Cabin Furniture  Gazebos

Gazebos  Cabin Exterior Pics

Cabin Exterior Pics  Floor Plan Examples

Floor Plan Examples